Trustworthy Standardized Cement

Late-stage strength, acid and alkali resistance, chemical resistance, and resistance to seawater corrosion are all superior to ordinary cement.

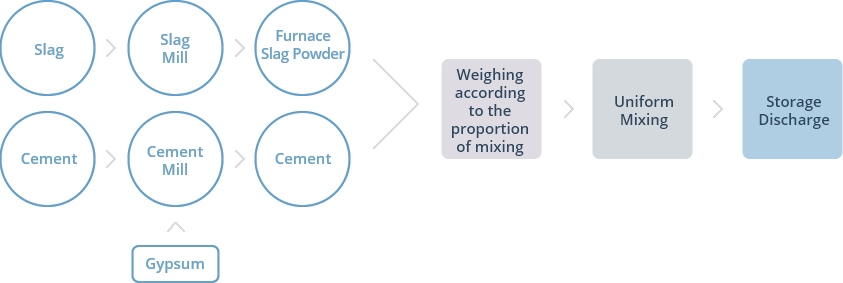

Portland Blast Furnace Slag Cement

Late-stage strength, acid and alkali resistance, chemical resistance, and resistance to seawater corrosion are all superior to ordinary cement.

It is a homogeneous mixture made of Portland cement and water-quenched blast furnace slag powder. The weight percentage of blast furnace slag in Portland blast furnace cement should be in the range of 25 to 65. The production method of Ruentex blast furnace cement involves precisely mixing separately ground Portland cement and water-quenched blast furnace slag powder, resulting in high-quality and highly active blast furnace cement. Is superior than other manufacturers that grind clinker and slag together.

Portland Cement

Late-stage strength, acid and alkali resistance, chemical resistance, and resistance to seawater corrosion are all superior to ordinary cement.

Type I (General) Cement: Supplied for general construction and public projects such as the Taipei-Yilan Expressway, etc.

Type II (General) Cement: Used in projects like the Zhongzheng Airport runway and phase two projects, as well as the Lanyang Tunnel.

Type II (Low Alkali) Cement: Used in projects such as nuclear power plants and Taiwan Power Company hydroelectric power plants.